Sage X3 has a function that will compute the simulated cost of a product, a group of goods, or all products at a site depending on the cost type routing alternative, BOM with or without immediate update, and create a report that summarizes or details the results.

Simulations of the cost are often used to estimate the price of a project as a function of its specifications (new BOM, new component, new route).

Simulated cost calculations are based on routing data time and valuation dimension data for the work centers associated with the route during processing.

As part of the calculation for raw materials, the process attempts to figure out the receipt overheads for each raw material.

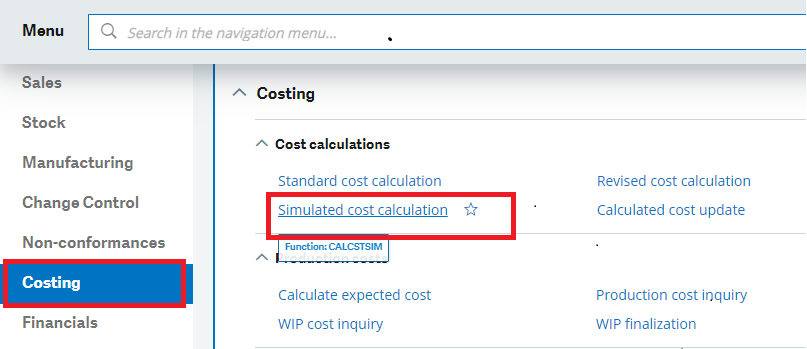

To find Simulated Cost Calculation, navigate to:

All>>Costing>>Simulated Cost Calculation

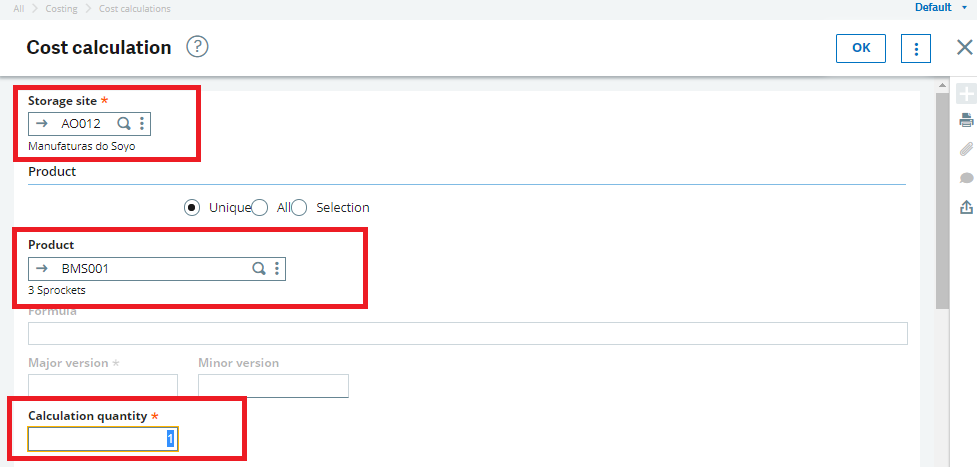

Steps:

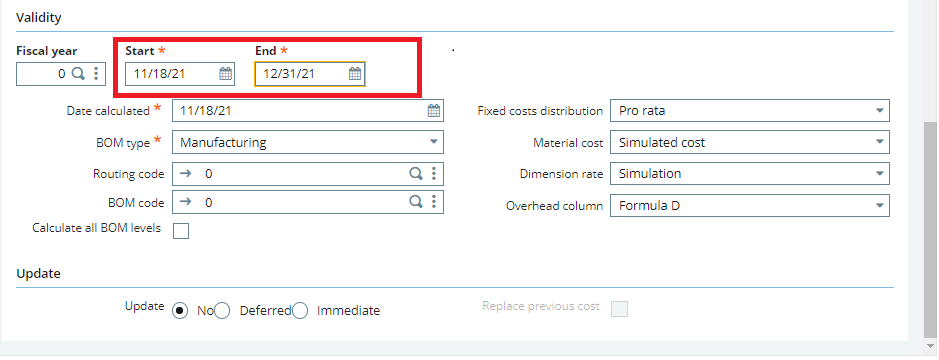

Several options are available for the user to determine a simulated cost, including: a selection of calculation quantities, a selection of raw material valuation, overheads, a valuation dimension rate selection, and a posting method for fixed costs.

Whenever a cost calculation includes a multi-level BOM or encompasses several products, the process is exclusive to a particular site, so another user cannot launch a cost calculation at the same time.

The system examines selected products in decreasing order of the lowest level of codes if a selection of products is requested.

The calculation of a BOM with or without the lower levels consists of reading the component costs at the first level and transferring them to the cost of the parent product.

When using BOM split, the computation takes into account component costs at the top level, as well as all components in decreasing order of the codes at the bottom level.

When the costs of the sub-levels have already been estimated, a calculation ignoring the lower BOM is warranted for an update.

Notes on the cost of materials and subcontractors:

Materials:

A material does not have a component by definition. When the cost is defined as “calculated” rather than “input,” the “Material cost selection” field is utilized to decide how the cost is computed.

Subcontract:

The following is an example of how to value a subcontract service in a production context:

- If the operation has a reference price, it is taken into account.

- If the valuation method is on the product site, the price of the valuation method is taken into account.

- Locate a price list.

If a price list cannot be identified, the standard cost might be used if the PURPRICE – Standard cost default price list option is set to 1. Yes.

The calculation procedure is systematically based on the validity start date of the cost to search the subcontracting service without Work Order and the provided material list prices offered by the subcontractor and to search the material list price and the choice of Bill Of Material components.

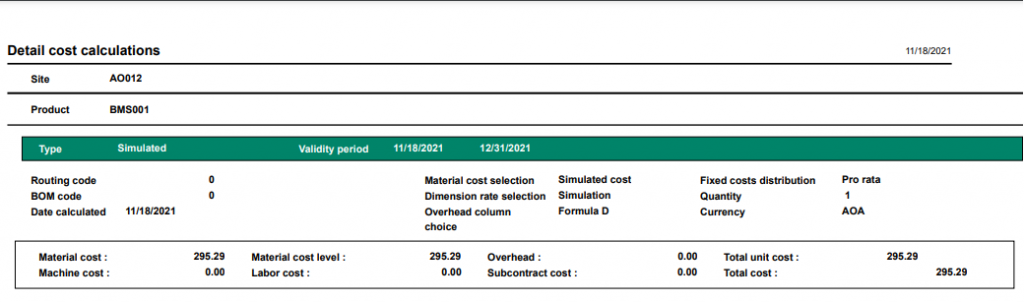

After the successful run of the Cost Simulation process the report ITMCOST will be printed that summarizes or details the results.