Optimize Inventory Levels through Re-Order Point Processing in Sage X3

Optimize Inventory Levels through Re-Order Point Processing in Sage X3

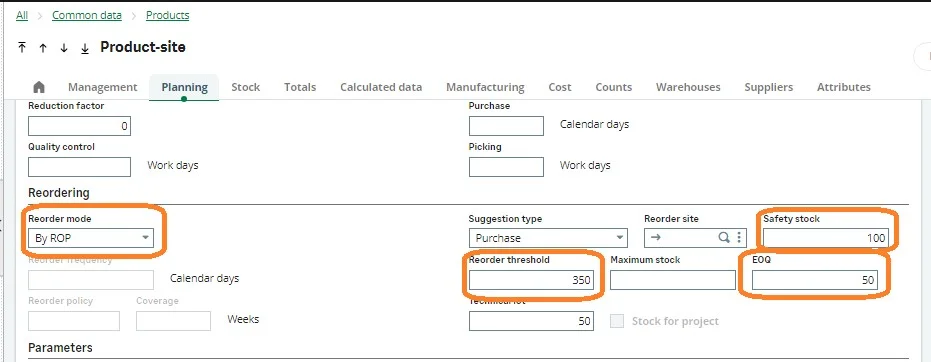

To set up the ROP reorder mode navigate to: Common data> products> product-site

- Reorder threshold: the stock level from which reordering is triggered.

- Safety stock: it features an additional stock implemented to be able to face a longer deadline to obtain stock or a request higher than the average request.

- EOQ (Economic order quantity): the minimum reorder quantity from a supplier.

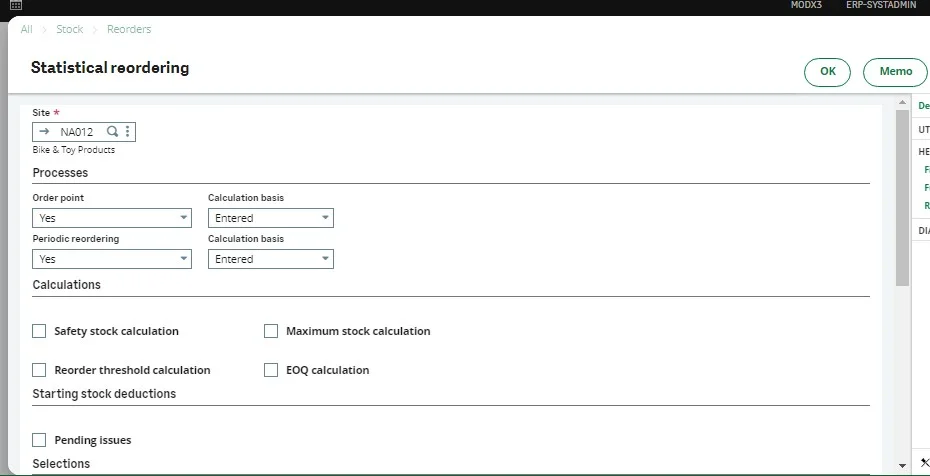

Statistical reordering:

To run this function, navigate to: Stock> reorders> statistical reordering

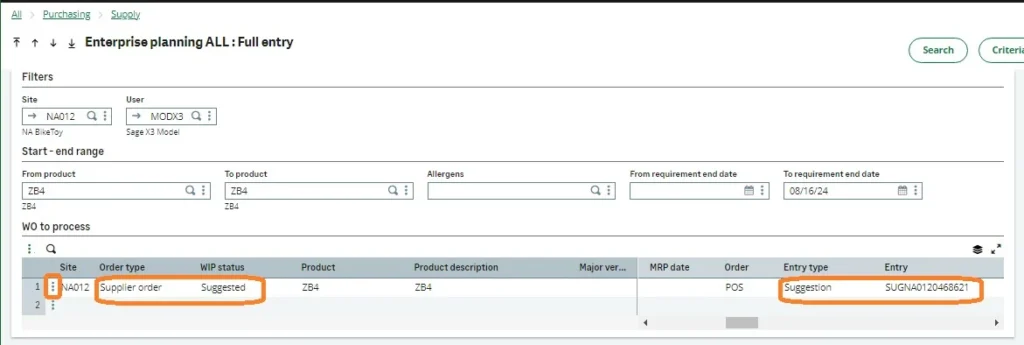

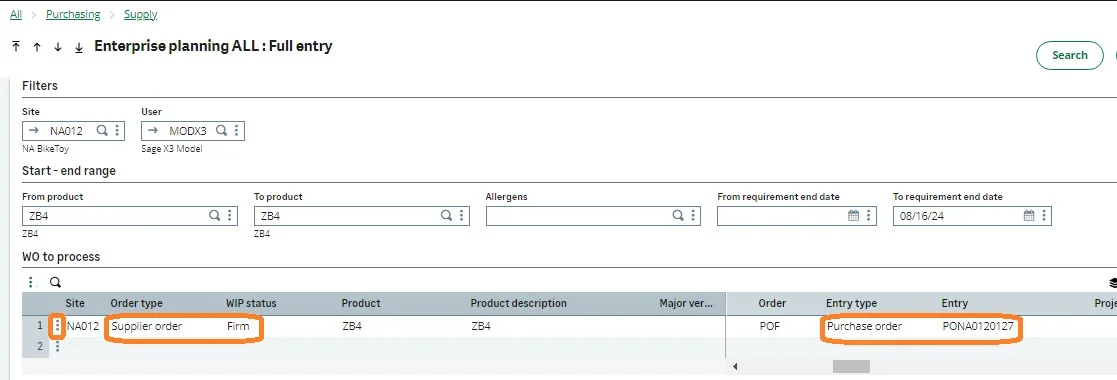

Navigate to: Purchasing> Supply> Enterprise planning

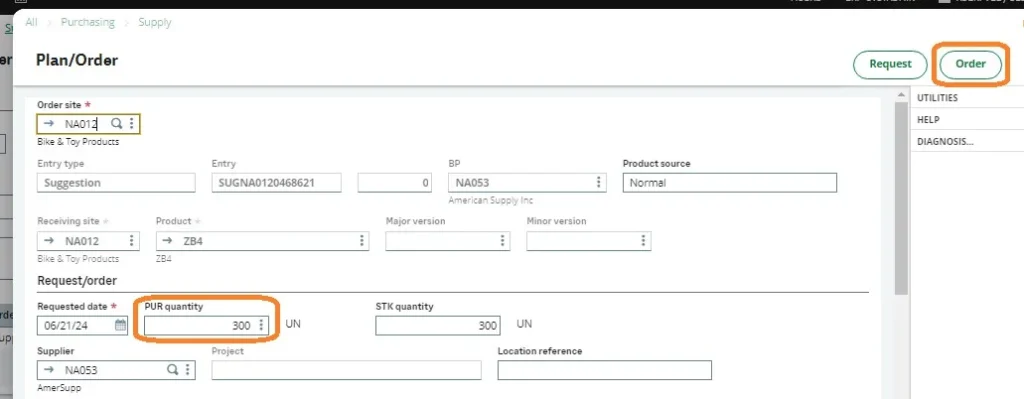

Note that the suggested purchase quantity is 300 units. Click ‘order’ at the top right of the screen and a log reading will be generated with the Purchase order number created.

NB: the suggestion will be converted to a complete order as long as details for the supplier and price of the product have already been defined and linked to the product beforehand. However, necessary adjustments can still be made once the order gets generated.

About Us:

Greytrix Middle East Subsidiary of Greytrix India Pvt Ltd, Headquartered in Mumbai. It is a leading Sage business partner and ISV Partner offering Consulting, Implementation, and development services for Sage X3, Sage 300 People (HRMS), and Sage Intacct, which covers Dubai, Saudi Arabia, and Qatar region.

Our methodology involves a techno-functional expert team to analyze the client’s business processes, workflow, current system situation, and plans. Then, based on the analysis, we propose solutions that meet their requirement regarding the product consideration. In addition, we ensure to serve our clients with robust, future-proof, business-critical solutions that deliver best practices, processes, and functionality designed specifically for the business and its people.

We offer professional services such as Implementation and Configuration, Business Process Analysis, Project Management, Integrations and Migrations, and Technical & Functional Support, along with enhancements within Sage X3, Sage 300 People (HRMS), and Sage Intacct across various industry verticals like Process Manufacturing (Food & Beverages, Chemical), Discrete manufacturing (Automotive, Textile & Apparel), Non-Profit, Health-care Industry and Services Industry (Financial, Software & Engineering), Distribution (Transportation & Logistics).

Our Partnerships