A Work order is an order to make one or more products. Conventionally, the work order uses a bill of materials (BOM) to create a list of materials to be issued, and a routing to make a list of operations to be performed on work centers. Work orders dictate what product need to be manufactured, what raw materials are going to be required to manufacture the product, and which work center that the product needs to pass through in the manufacturing process.

Basically, work order uses a bill of materials (BOM) to create a list of materials to be issued, and a Routings to make a list of operations to be performed on work centers. An operational routing defines the formalization of the steps required for a manufactured product (finished or semi-finished). Its production process, as well as the sequencing of the operations to be completed. In Standard Sage X3 user can create a work order without routing code with the help of below steps.

Follow the below steps for the setup:

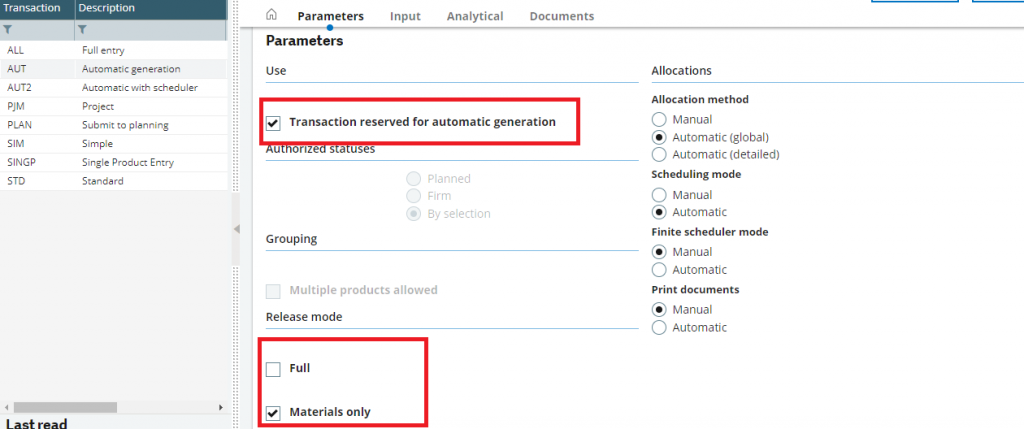

Navigate to: Setup >Manufacturing > Entry transactions > Work orders

- Select Automatic generation entry transaction from left list

- In the work order entry transaction reserved for automatic generation, the Transaction reserved for automatic generation checkbox in the Parameters section is selected.

- Select the Materials only checkbox in the Release mode block and clear the Full checkbox, as shown in below figure. With these options selected there will be no checks run for the routing and routing code.

4. After changes do the validation of entry transaction.

With these options selected there will be no checks run for the routing and routing code.

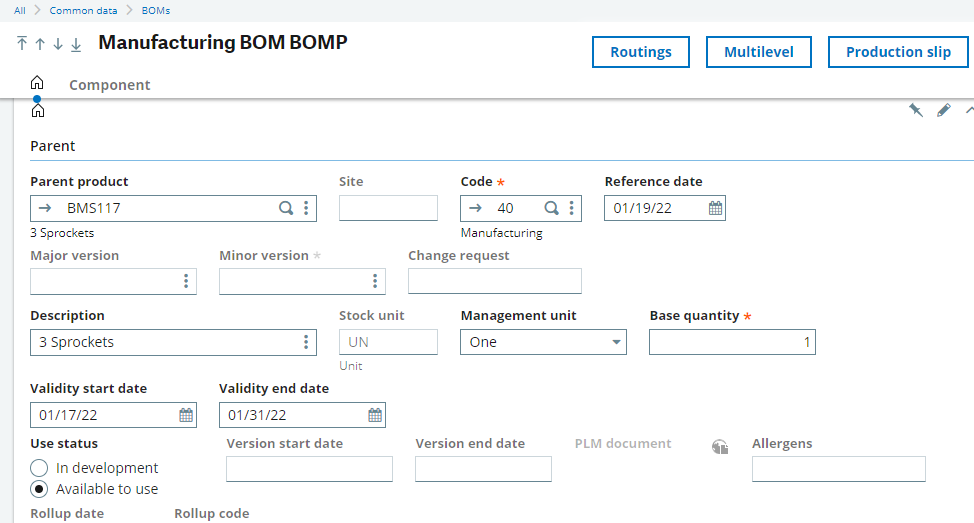

Now, we will create Production BOM without routing code.

Navigate to:Common Data >BOMs > Production BOMs

- Enter a Parent product, BOM code, validity dates and components values.

- Use status should be mark as an “Available to use”

- Create a BOM, as shown in below figure.

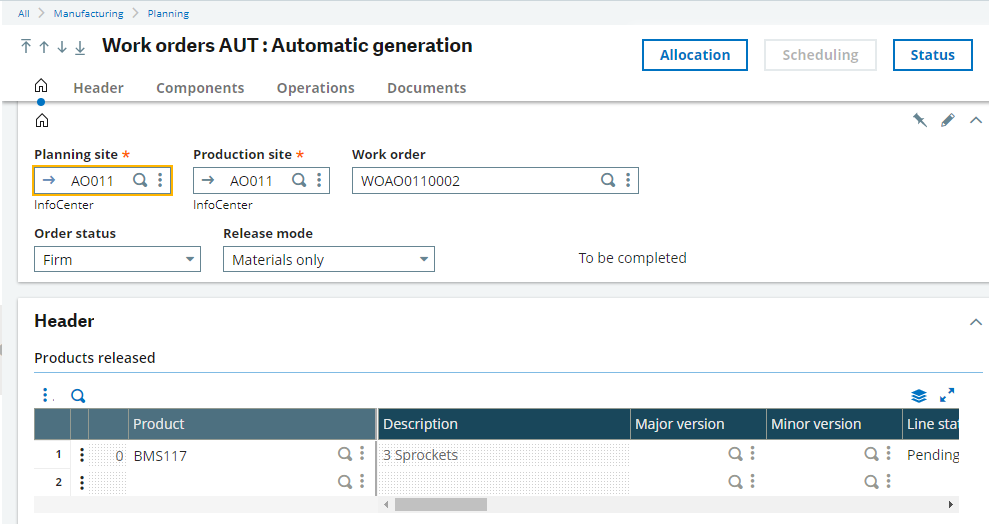

We will create now Work order with help of above created production BOM.

Navigate to: Manufacturing > Planning > Work order

- Select that Automatic Generation transaction

- Enter Mandatory fields values as shown in below figure.

- Create a work order.

Now, you can see in below figure system allowed user to create work order without entering routing code in routing section.

With the help of above steps, we user can create or import Work order without routing.