Recently we had a requirement from one of our client in which we have done customization on Requirement Quantity field of components tab in the Work Order screen. They are using stocking unit in “KG” in Sales Order but for work Order they require quantity to be converted in the “NOS”. So now by using our customisation the system is configured in such a way that Work order will generate a calculated Requirement quantity based on the NOS stocking unit and values entered in the Sales Order.

New Stuff : Automatic Product Code and Description generation from the User Input

We will see the functionality in detail:

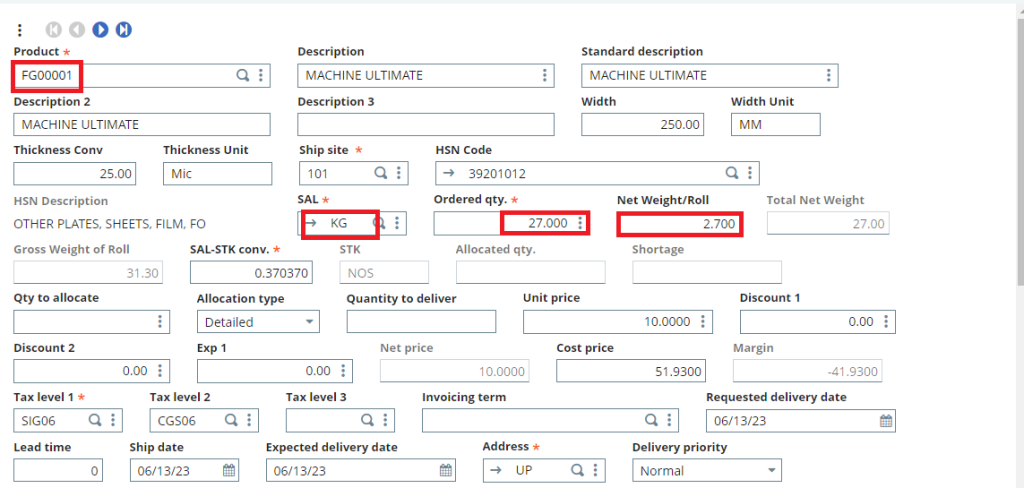

Navigate to: Sales -> Order

While creating the sales order the user will enter the ordered qty. as 27kg and define the net weight/roll as 2.7kg (which means 1nos of the FG product = 2.7kg)

As per the calculation, 27 kg divided by 2.7kg = 10 rolls (which means 10 nos of FG product are required to produce)

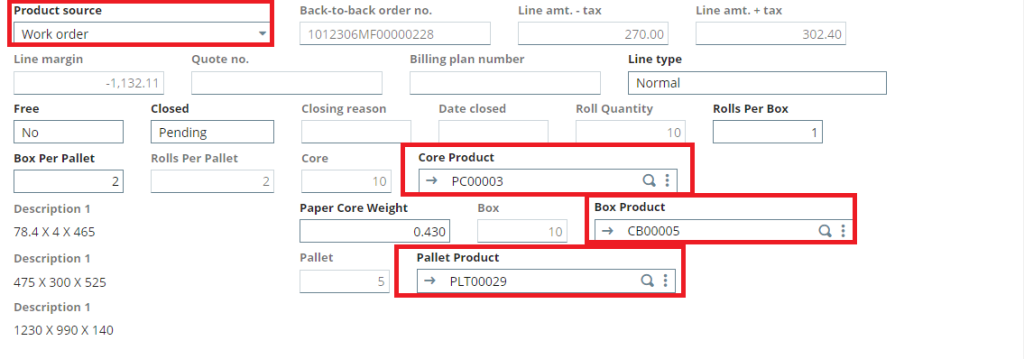

As shown in the above screenshot, we have added new fields “Core Product, Box Product, Pallet Product with their respective quantities” in the Sales Order screen.

After the sales order creation, the user will create the work order through multi-level planning from the sales order screen.

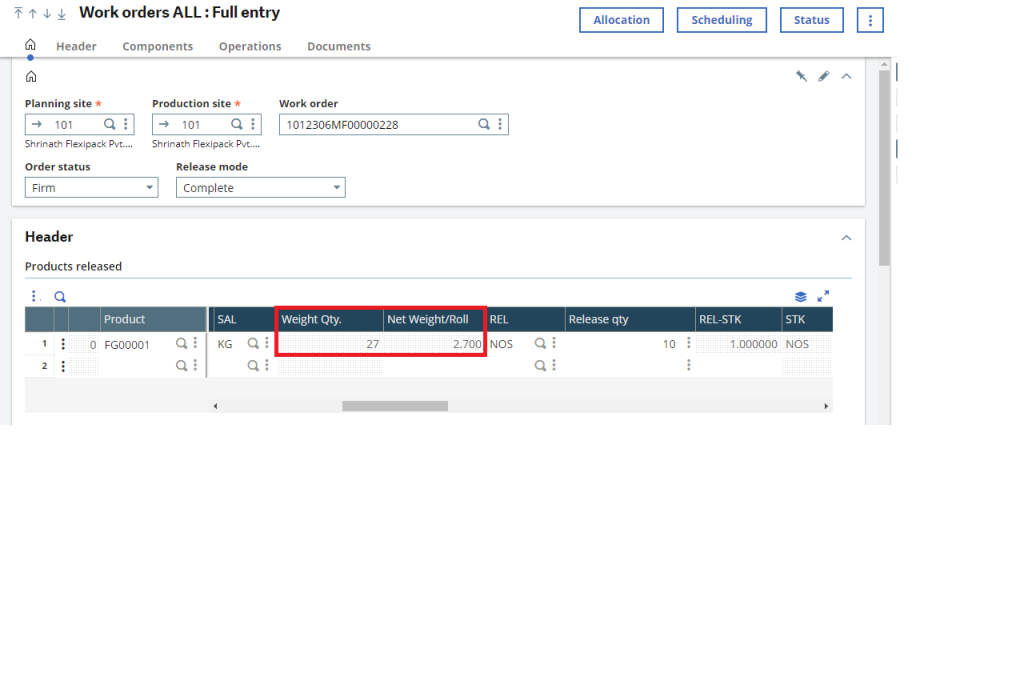

Navigate to: Manufacturing -> Work Order -> Header Tab

So, as per the requirement from the client, the sales order has been created with the ordered qty as 27kg with a net weight of 2.7kg and the system is suggesting to produce 10 NOS of FG product.

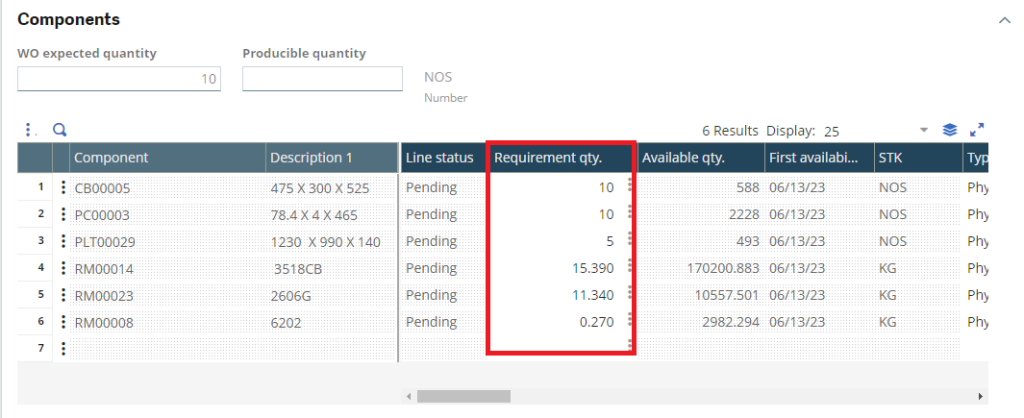

Navigate to: Manufacturing -> Work Order -> Component Tab

So with the packing details whichever the data is entered in the sales order screen the same will be flown here in the components tab such as Core Product, Box Product, Pallet Product with quantities. Also weight qty. and Net weight/ Roll will be flown as it is in the header tab of the work order screen. In Release Quantity of Header tab, user can enter previously calculated 10 NOS manually. And the components which we have saved in the production BOM will flow in the work order screen too, which is our standard process. As shown in the above screen shot. But for those BOM products, requirement quantity will be generated by using formula.

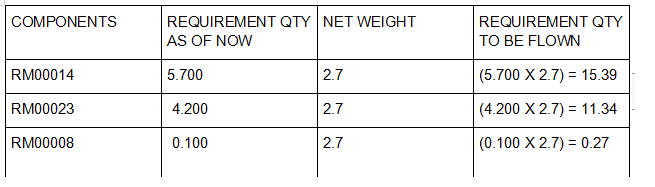

For Example -:

The net weight/roll which is presented in the work order screen that net weight should get multiplied by the component qty of BOM to get the requirement qty.

This calculation should reflect only for the component which is flowing from the Production BOM. As shown in the above screenshot, calculated qty is been flown in Requirement Qty of components tab of Work Order.

In this way quantity calculation will be done for components in the Work Order by using formula on the basis of BOM Quantity and Sales Order values.