We do have request to control the scrap when the manufacturing of the product needs to be done. If as such control are not placed then the end user will not hold any control on the wastage while preparing the finished goods.

This setup can be done within the Sage X3 functionality toachieve the control on scrapping out the material while making the production tracking.

This setup can be done in the below way as follow:

- On the product site

- In Routing

On Product Site:

The maximum this percentage of the loss while manufacturing of finished goods. This shrinkage is most applied on the raw material,this shrinkage is carried to the routing as well.

This value will be in percentage and proportionate quantity of the produced quantity will be considered while considered.

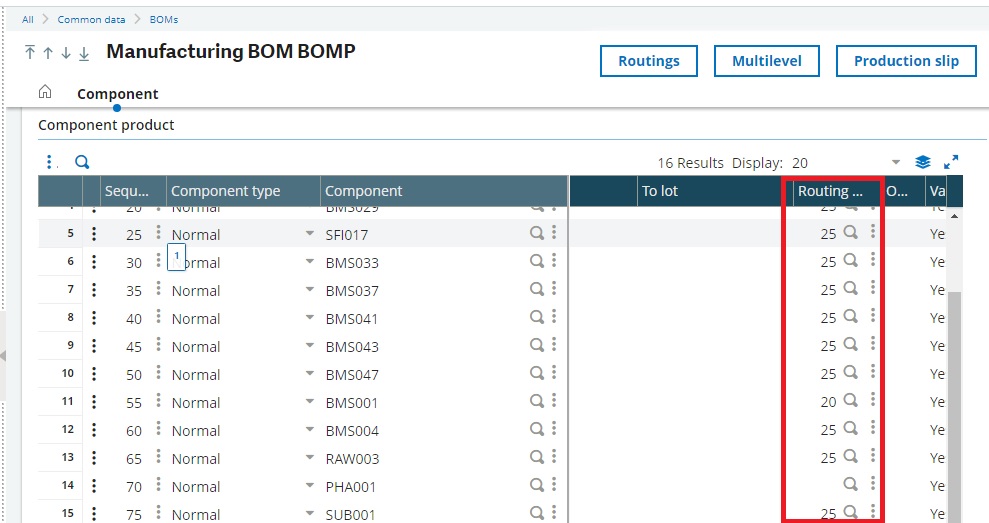

Routing screen

We do have the screen on the routing which fetched the value from the master, but incase user wish to modify it from the screen then it can be modified.

The shrinkage on the routing can be assigned to the routing in the following way:

On the BOM Level we assign the component and each component has its own Operation, this operation code on the Component grid indicates that particular product is consumed in mentioned operation.

Each operation has its own set of products that are consumed, during this consumption wastage or shrinkage can be taken place.

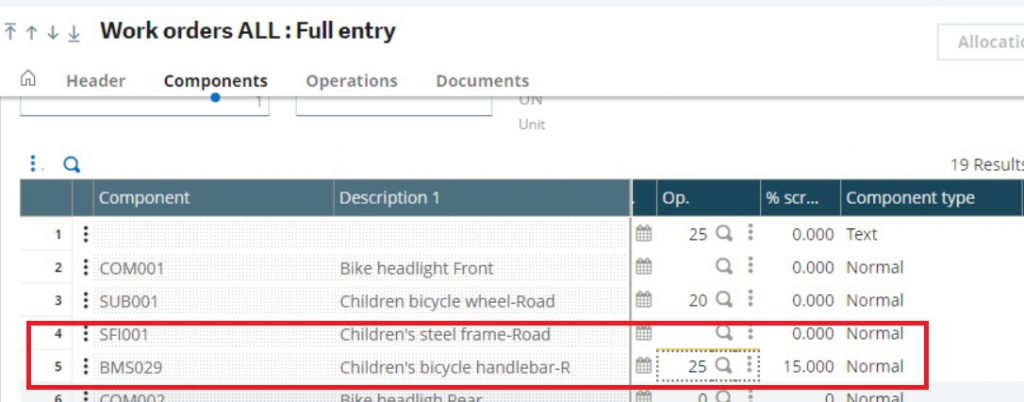

This shrinkage is then carried to Workorder and according to it the quantity is increased in Material tracking.

The above are the points which we need to do for the setup. Below are the reflection we can observe in the Work order.

On the work order, when we track finished goods according to the finished goods quantity the component are filled in raw material tab.

At the time when the raw material are tracked, quantities are being populated in the respective product and the quantities are increased according to shrinkage.

This increase in quantities help the user to allow the quantities to get perfectly allocated, so incase even if it is shrinked at the time of the Production it should not affect the process of due to shortage.

Example:

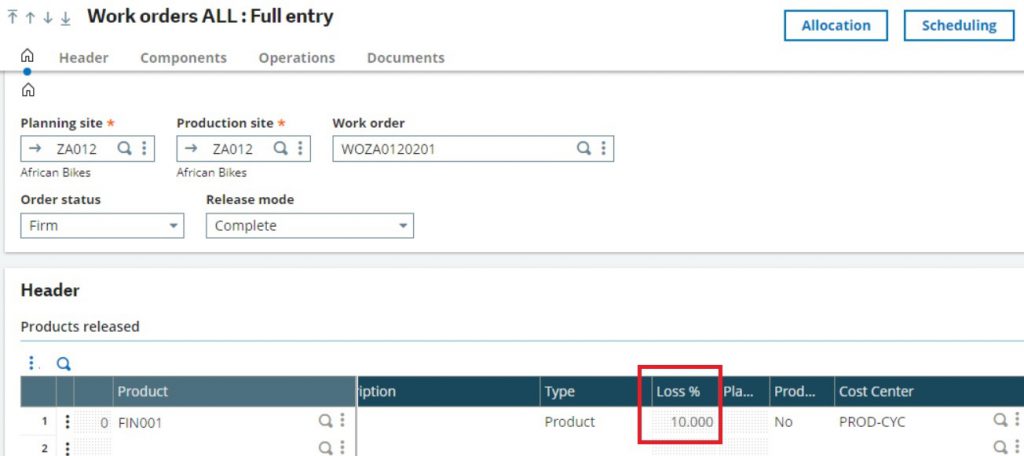

The shrinkage on the finished goods is mentioned when the final product is produced:

This is the loss percentage consider in the assumption while we make the production tracking, and this loss percentage are being carried from the Product site as mentioned earlier.

The second setup which we have done in the Routing is being carried in the Component as shown below:

This is being carried from the second setup which we have done in the routing while we define the BOM. This will indicate the scrap that will be generated from this product.