The automatic deallocation processing of material linked to production for a given site, a given period and selected work orders can be initiated using this function. This processing can deallocate the materials based on the initial allocation type (global or detailed).

A deallocation processing can be initiated based on the type of initial allocation (global or detailed) for materials assigned to a given site, a given period, and selected work orders.

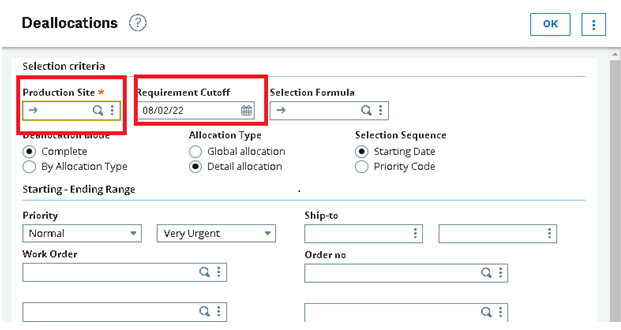

Below are the selection criteria for automatic deallocation function.

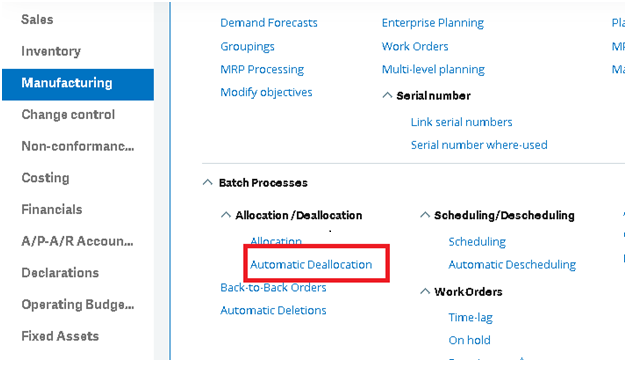

Navigation:

All >> Manufacturing >> Automatic Deallocation.

Selection criteria:

Production site: The site associated with the user is suggested by default.

Requirement cut off: This field makes it possible to select the materials which requirement date is prior to the date mentioned. By default this date us initialized to the current date. Material requirement dates that are prior to the mentioned date are selected by this field. By default, this field is initialized with the current date.

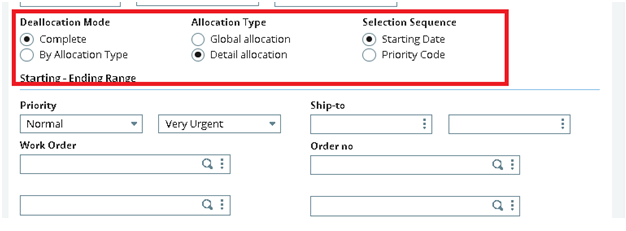

Processing type:

This block is used to select the materials that must be deallocated based on their current allocation status.

Deallocation mode:

- Complete deallocation: The materials in the selection are deallocated irrespective of their allocation status of origin (global, detailed, shortage).

- By allocation type: It is possible to choose to deallocate only those materials in the selection that were initially globally allocated, or only the materials that very initially allocated in detail.

Selection order:

The purpose here is to specify the order in which the allocations must be executed for the various WOs in the selection. The purpose of the order specification is to specify the order in which the allocations must be performed for the various WOs which make up the selection.

- By start date: the WOs are processed in the order of their start dates: For a similar start date, the priority code of the WO is taken into account. In addition to processing WOs in order of their start dates, priority codes are taken into consideration when WOs have similar start dates.

- By priority code: the WOs are processed by decreasing priority order (Very urgent, Urgent, Normal). With an equal priority level, the system examines the material requirement dates. With identical priority levels, the system examines the material requirement dates for each WO in decreasing order (Very urgent, Urgent, Normal).

Start/End ranges:

These ranges are used to select the materials to be processed. The possible ranges are:

- Priority

- Work order no.

- Project

- Destination

- Order number

- Released product

- Material

At the end of the processing, a log file can be printed. This log mentions the deallocated quantities for each work order and material.